Introduction to ISO 45001 and Occupational Health & Safety Management Systems

You want a workplace where people go home healthier than they arrived, and where safety isn’t a project but the way you run the business. And ISO 45001 gives you that operating logic. It’s the international specification for an Occupational Health and Safety Management System (OHSMS) that helps you identify hazards, control risks, and continuously improve safety performance.

If your organisation operates in Singapore, aligning the OHSMS with the Workplace Safety & Health Act (WSHA 2006) and Ministry guidance makes the system both practical and defensible. This standard replaced OHSAS 18001, shifting the focus from bureaucratic compliance to leadership, risk-based planning, and worker participation, and it’s the kind of change that actually reduces incidents.

(Image Source: Google Gemini)

Key Workplace Safety Statistics: Why ISO 45001 Certification Matters

Numbers persuade faster than slogans. So here are a few to give you a look into why ISO 45001 matters.

- A global study of ISO 45001 adoption found certified organisations achieved an average 32% reduction in workplace injuries within two years.

(Image Source: AAA-ISO Survey)

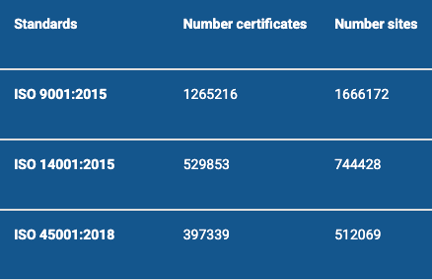

- Third-party analyses report 397339 active certificates worldwide and place ISO 45001 among the top management-system standards, just behind ISO 9001 and ISO 14001, making it the third most adopted ISO standard.

These facts underline that workplace safety Singapore practitioners and buyers expect systematic, certified approaches when they assess partners and suppliers.

What Is ISO 45001?

ISO 45001:2018 represents the globally accepted standard that defines requirements for an OHSMS. Its purpose is to prevent work-related injury and ill health and proactively improve occupational health and safety performance.

The standard adopted the High Level Structure used by other ISO management standards, so you can integrate systems across quality, environment, and safety. It formally superseded OHSAS 18001, and organisations that held OHSAS certificates were expected to migrate to ISO 45001 under accreditation transition timelines.

But wait, is ISO 45001 mandatory in Singapore?

While ISO 45001 is not legally required in Singapore, implementing it supports compliance with the Workplace Safety and Health Act (WSHA 2006) and related regulations oblige you as an employer to have an effective safety management approach and to manage risks reasonably and practicably. Implementing an OHSMS to ISO 45001 standards is widely accepted as meeting those obligations and demonstrates strong legal compliance Singapore-wise.

Why ISO 45001 Certification Is Important for Organisations

When you choose to implement ISO 45001 and pursue ISO 45001 Certification Singapore, you’re not buying a plaque. Instead, you’re building a system that lowers risk, improves outcomes, and strengthens trust.

First, the standard scaffolds legal compliance and maps directly to duties under WSHA 2006, helping you meet regulatory expectations and reducing the chance of enforcement action. The operational benefits are real as well because certified organisations frequently report improved continuity as fewer incidents mean less downtime, lower absenteeism, and steadier throughput.

Third, the human benefits are non-negotiable since safe workplaces boost employee wellbeing, retention, and morale. And when your people feel safe, they perform better. Fourth, there’s commercial value as clients and tenders increasingly ask for certified OHSMS as proof of mature risk management; certification improves your competitiveness in APAC supply chains.

Finally, because ISO 45001 shares a structure with ISO 9001 and ISO 14001, integrating systems reduces duplication and improves management efficiency across functions.

Core Clauses and Structure of ISO 45001

The ISO 45001 framework is built around seven core clauses (4 to 10). Together, they form a continuous loop of planning, doing, checking, and improving.

Clause 4 – Context of the Organisation

You start by understanding who you are, what you do, and what internal and external factors affect your operations. This clause ensures your OHSMS fits your actual business environment and meets the needs of interested parties.

Clause 5 – Leadership and Worker Participation

Leadership commitment is the foundation of effective safety management. You define roles, responsibilities, and communication channels that let every employee contribute to the success of the system.

Clause 6 – Planning

Here, you identify risks, opportunities, and legal requirements under the WSHA 2006, then set measurable OHSMS objectives. It’s about being proactive and controlling hazards before they control you.

Clause 7 – Support

This clause deals with the resources, competence, awareness, and documented information that keep your system functioning. In practice, it means ensuring your team has the skills, training, and communication needed for a safe operation.

Clause 8 – Operation

You implement your plans here by defining controls for routine and non-routine work, emergency procedures, contractor management, and procurement. Essentially, this is where your OHSMS turns policy into action.

Clause 9 – Performance Evaluation

This is your feedback loop. You monitor, measure, and evaluate how well the OHSMS performs through internal audits and management reviews. The goal is data-driven decisions, not assumptions.

Clause 10 – Improvement

No system is static. You investigate incidents, correct non-conformities, and apply lessons learned to drive continual improvement. Over time, this clause ensures your safety culture matures, not just your documentation.

These clauses are the backbone of any credible OHSMS and define the practical expectations auditors will check.

Benefits of Implementing an ISO 45001 Management System

When you implement an OHSMS aligned to ISO 45001, the gains are measurable and strategic.

- Safety outcomes improve: Rigorous planning and control reduce incidents and near-misses, which translates directly into fewer treatment costs, less operational disruption, and a safer reputation in the market.

- Absenteeism and downtime fall: Fewer incidents mean fewer interruptions to production or service delivery, which directly protects revenue and service SLAs.

- Insurance and liability exposure come down: Insurers and underwriters notice mature risk control, and better controls can translate into improved premium terms or reduced claims experience.

- Workforce engagement rises: People who feel protected are more productive, less likely to leave, and more willing to follow process improvements.

That’s not all. Integrated management (linking safety to quality and environment) reduces duplicated audits and administrative overhead because there’s one system, less friction, and clearer management data.

ISO 45001 Certification and Implementation Roadmap

Most mid-sized organisations complete the journey in six to nine months, provided responsibilities are clearly assigned to the HSE Lead, HR, and Compliance teams.

- Initiation & leadership commitment: secure resources, define scope, appoint project lead.

- Gap analysis & planning: map current practice to ISO 45001 clauses, set objectives and KPIs.

- System design & documentation: craft policy, processes, risk registers, and documented information.

- Implementation & training: deploy controls, run OHSMS training, engage workers.

- Internal audit & management review: audit, correct, and confirm readiness for certification.

- Certification audit & continual improvement: stage 1 and stage 2 audits, receive certificate, then maintain through surveillance.

This roadmap keeps the effort tactical and time-boxed so leaders can see progress every sprint.

Common Implementation Challenges and How to Overcome Them

Of course, you’ll meet some resistance, resource limits, and ambiguity. Here’s how to address them pragmatically:

- Leadership buy-in — run a short, focused executive workshop and set a handful of visible KPI targets so leaders can track return on safety investment.

- Risk assessment quality — move from task lists to process mapping and cross-functional hazard identification to uncover systemic risks.

- Worker participation — build worker safety committees, run hands-on hazard hunts, and create a rapid feedback loop for safety suggestions.

- Documentation overload — adopt a single electronic records platform and align procedures with your ISO 9001/14001 records to avoid duplication.

- Sustaining momentum — schedule quarterly performance reviews, promote safety wins publicly, and keep improvement stories visible.

These fixes are tactical, fast to deploy, and directly address the pain points auditors and frontline teams call out.

How Artan Consulting Supports Your ISO 45001 Journey

Artan’s practice emphasises pragmatic, expert-led consulting, training, and audit support. We’re built for organisations that want actionable systems, not paperwork.

You’ll benefit from Artan’s approach because they combine technical rigor with practical delivery:

- Tailored OHSMS design and gap analysis: Artan’s consulting model starts with a focused gap analysis mapped to the ISO 45001 clauses, so you see exactly where effort is needed and how much.

- Practical audit readiness and internal audits: We run internal audits and mock certification exercises that mirror what accredited auditors will check, which removes surprises and shortens the path to ISO 45001 Certification Singapore.

- OHSMS training and competency building: Through the Artan Academy and tailored training calendars, Artan builds competence across HSE leads, HR, and frontline supervisors so the system sticks. Not just during the project but long after certification.

- End-to-end delivery and post-certification support: From gap analysis through certification and into surveillance support, we emphasise measurable outcomes like documentation, audit evidence, training records, and post-cert KPIs so you can sustain improvement without constant external input.

- Integrated systems and cross-disciplinary experience: Artan already advises clients on ISO-aligned systems (ISO 27001 / ISO 42001 and others). That cross-discipline experience makes it easier to integrate quality, environment, and safety systems, reducing duplication and cost.

So if you’re already working with Artan on another ISO, adding an OHSMS is a smooth extension.

Final Words

With us, you’re not buying a certificate but investing in a system that protects people, preserves productivity, and builds trust. Pursuing ISO 45001 Certification Singapore is a visible way to align with the WSHA 2006 duty of care, improve outcomes for your workforce, and make your business more resilient.

If you want a partner who understands standards, runs realistic OHSMS implementation programmes, and builds capability through OHSMS training and audit readiness, Artan Consulting has the practical services and learning resources to get you certified and keep improving.

Contact Artan for a readiness review and start turning safety commitments into measurable results.